- info@esbsa.com

- +966 55 820 1730

Delivery deeper machine connectivity, advanced insights that drive action, and enable automation across the manufacturing stack from production and maintenance to quoting and planning.

With Wimera, we ensure that all people and systems within the factory have the accurate and real-time production data they need to make better, faster and more effective decisions at scale whether it is hundreds or even thousands of machines, in one plant or multiple manufacturing plants. This helps you nail down your operational data, ensuring that you have an accurate view of your shop floor performance.

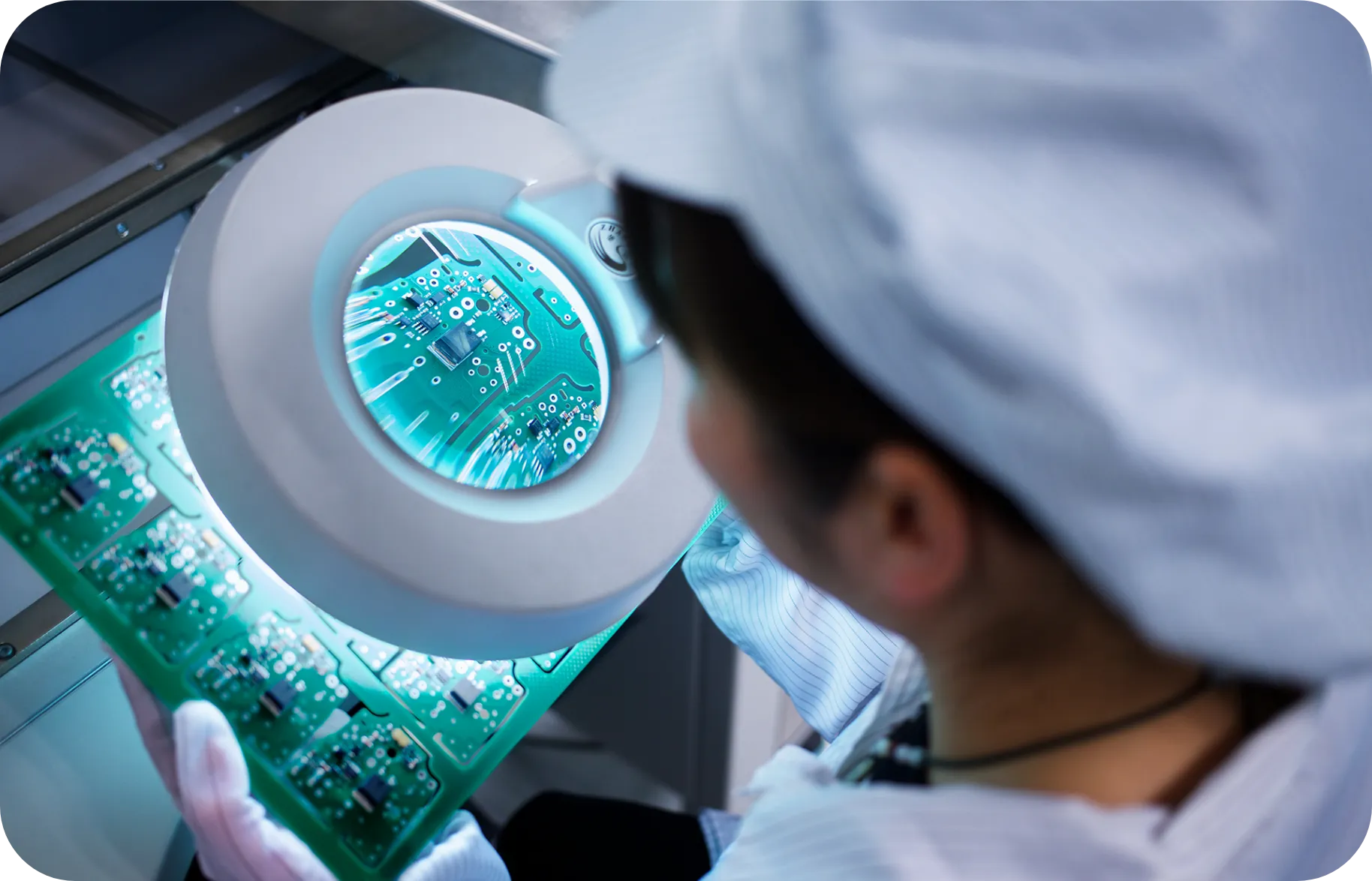

Currently, a majority of the manufacturing industry operates with primitive maintenance strategies, often maintaining their equipment based on a reactive or calendar-based approach. The reasoning for this is that most manufacturers do not have the machine condition data to inform them of the operational health of their equipment.

With Wimera, you enable instant access to machine health and diagnostics for a real-time look at your machine performance. But more so, machine monitoring provides an important machine status: Is the machine being productive or not?

Empower shopfloor operators with the right tools to meet production targets by visualizing real-time performance, and identifying key issues.

By enabling smart decisions with real-time data, your operators and management know what’s happening within your factory in real-time, down to individual parts and elements in operation.

Wimera enables predictive maintenance throughout the enterprise, through utilizing IIoT to gather and analyse data about assets, equipment or machinery. Sensors and other instruments collect data about equipment status to detect any issues that may need to be addressed to prevent future outages and unnecessary downtime.

By gathering and transmitting equipment performance data in real time, Wimera can run predictive maintenance analytics to identify any potential issues that may result in equipment failure. This process helps organizations better predict the chances of outages or other disruptions so that they can take a proactive approach to maintenance.

Sometimes the problem isn’t on the machine level; it could be the upstream process that is managing the machine. By utilizing data to visualize this, Wimera helps you implement changes in flow or other feedstock proactively to improve your uptime.

Using data effectively to pinpoint where we can increase the response time at the machine level, enables us to optimize several areas at once for a multiplier effect on uptime.

Simulate real use cases for your machines in a simulated digital twin environment to predict and analyze the performance of your equipment within a manufacturing environment. By modelling this asset twin data, you can predict anomaly detections, failure predictions, and have a reduced risk of loss or catastrophic disruption through robust monitoring.

This increased insight for performance behavior is enabled effectively with Wimera by understanding and utilizing assets in live production use cases.

Wimera helps manufacturing enterprises move from reliance on operator skill sets and knowledge silos from a few experienced people.

With Wimera, you can start adjusting processes, developing work standards, monitor your parts closely, and deploying technology that aids in enhancing the quality of your operations. Wimera enables you to do this in a cost-efficient manner while ensuring that the end result, leads to customer satisfaction.